As you may have noticed (but I know that no one follows me xD) in the last 2 weeks I have not written anything because of the lack of the PC that has decided to abandon me and the super speed of priority mail, which has only the name of priority.

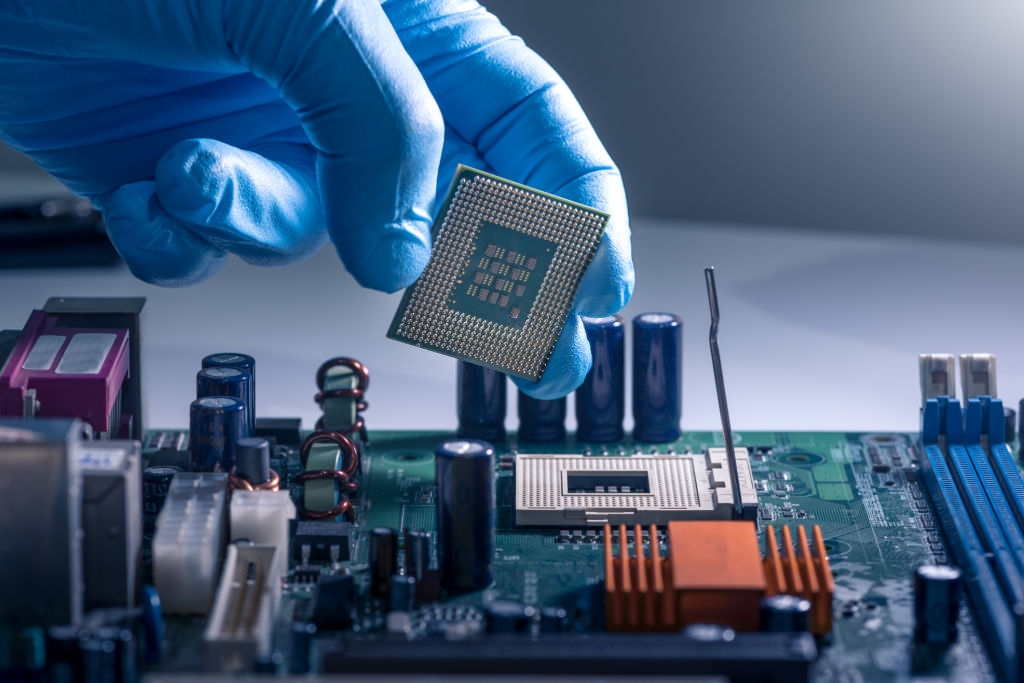

In fact, the PC after turning off suddenly and once turned on the screen was flashing black. So I decided to open the PC and check all the hardware. If you open a computer before touching electrostatic-sensitive components such as motherboard, CPU, etc. make sure that you have discharged all the electrostatic voltage of your body. To discharge the electrostatic voltage it is not necessary to have an ESD bracelet but simply touch the power supply of the PC off but still connected to the power outlet.

Usually when the screen flashes black without any video signal and the motherboard buzzer does not emit sounds, it almost certainly means that the problem lies in the motherboard. Once all the components were removed, in fact looking carefully at the motherboard I noticed 2 damaged electrolytic capacitors.

A damaged electrolytic capacitor is very easy to spot, you don’t need to be an electronics expert just a careful eye. When this type of capacitor fails, the flat top where there are small cuts becomes rounded and this means that the capacitor is to be replaced.

Needless to say, the damaged capacitors were of a brand as Vegeta of the lowest level would say in fact on the P5B there are many quality Panasonic branded capacitors but there are many that I presume to be recently Chinese and are positioned in critical points subject to a lot of heat (see the one next to the PCI-E 16x slot of the video card) where I would have preferred to see something more solid see Panasonic, Rubycon or more reliable brands.

Once you have identified the problem, that is damaged capacitors, the first thing to do is ask yourself: is it worth wasting time to repair a motherboard? The answer to this question for me was yes. In fact, despite the age of my main PC for now fully meets my needs and in addition, it is very difficult to find motherboards with new socket 775 at a decent price, also I do not consider this a good time to change the whole PC as the production process at 14 nm is around the corner and the DDR4 will begin to be marketed in a few months and not being able to change PC I decided to try with the repair. And then you want to put satisfaction: D?

After these considerations, the first thing to do is to understand how many Volts and what capacitors are in my case 6.3 V and 820 μF and buy them from a reliable brand. If you are undecided any of these brands is excellent Panasonic, Nichicon, Rubycon and remember to take them with a maximum operating temperature of 105 ° C. I personally recommend Ebay for small orders. In fact, if you only have to order 5 capacitors, the large distributors of electronic components below a certain minimum order threshold (usually € 90 excluding VAT) charge very high shipping costs.

In my case, given my positive experience with Panasonic capacitors, I decided to replace the exploded capacitors with Panasonic FL.

If you decide to use eBay, be careful with the shipment and ABSOLUTELY AVOID SHIPPING BY PRIORITY MAIL for 2 reasons.

- if it is lost it is your business you will not have any refund

- The disproportionate slowness for 5 capacitors I have waited more than 13 days

Once you have the new capacitors you can proceed with the removal of the old ones.

Identify the “pins” of the capacitors to be removed on the back of the motherboard

With pliers cut them as much as possible in order to completely or almost completely remove the protruding part (this will facilitate the work)

Once the feet have been cut, turn on your soldering iron and with the wider tip that you have used, use the desoldering braid to remove the tin from the components to be removed.

At this point, it is probable that a problem will arise or that even by putting the soldering iron to the maximum you cannot even heat the area touched by the soldering iron tip in the slightest. This is due to the PCB, in fact, all the large boards not only pc motherboards but also television boards and so on, are not made up of a single layer but many layers and among these is the number one enemy of the welders or solid ground (a very large copper layer that instantly dissipates the heat making it almost impossible to remove the components).

There are several ways to solve this problem first of all, as mentioned above, use the larger tip you have in order to transfer much more heat; if you have a much more recent motherboard than mine you could also have another problem, that of Lead-Free soldering (components soldered with an alloy that does not contain lead, this type of alloy has a much higher melting point than traditional alloys 60-40 and makes the job even more difficult). After some unsuccessful attempts with my 60W to 450 ° C soldering iron, I decided to go strong.

If you also want to use this method to keep in mind that if done incorrectly you risk doing only more damage.

I already had a problem with this type repairing a TV some time ago so I decided to equip myself for these situations and I purchased a 200W instantaneous soldering gun capable of exceeding 500 ° C (if you are interested in the soldering iron in question is this ). With this type of welder, you will not have problems in removing the tin but also, in this case, a problem arises; being the components connected to each other through a single piece of copper (solid ground plane) the components around the condenser to be removed get very hot with the risk of damaging them so I suggest you find a way to dissipate excess heat perhaps using a piece metallic.

Although the photo is not the best if you look carefully you can see how the heat is dissipated instantly even with an incandescent tip in contact with the PCB cools almost instantly. Once you can remove a bit of tin, continue to remove it using the desoldering braid and gently start to move the condenser being careful not to burn yourself, slowly the condenser should “come out”. After the difficult part of the job, all you have to do is weld the new capacitors. Always remember that capacitors are polarized components and must be positioned correctly !.

If the work has been done well, the result will be this

In conclusion this I do not consider it a guide to repairing all the problems of the motherboard but very often when the motherboard does not work the problem is due to the damaged capacitors. In more recent motherboards it is very likely that common electrolytic capacitors are almost absent but this type of capacitors are present

Unlike conventional radial electrolytic capacitors, aluminum organic polymer capacitors do not always ventilate and therefore it is difficult for the naked eye to distinguish those that work from those that do not work. A very simple method is to touch the various capacitors (BEING VERY CAREFUL) with the knuckles with the PC on, usually, the damaged ones heat up in a few seconds at exaggerated temperatures and this can indicate a malfunction of the component. If you liked this guide/article, don’t forget to share it :).